Channel Letter Fabrication: Essential Guide to Creating Professional Returns and Backs

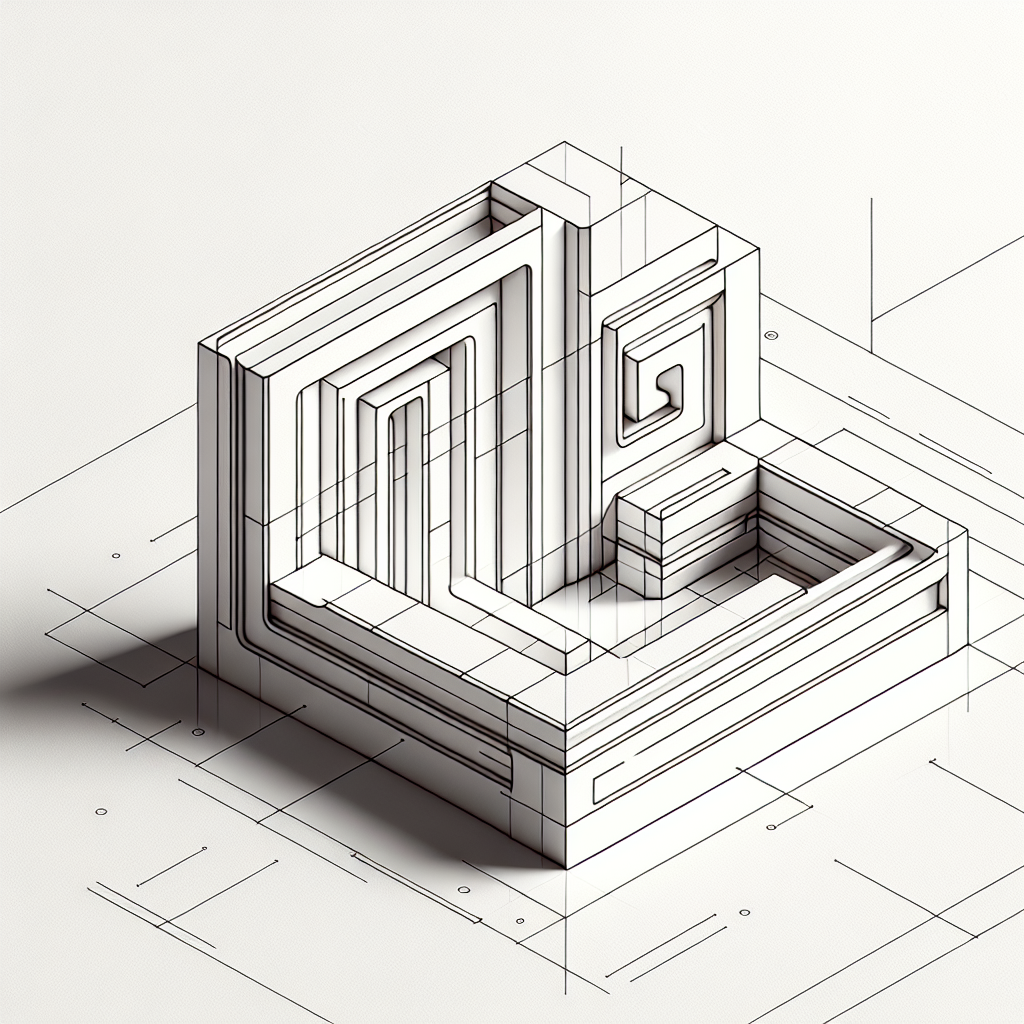

Understanding Channel Letter Construction in Sign Making

Hello Bay Area sign makers and fellow craftspeople! Today, we're diving deep into one of the most crucial aspects of channel letter fabrication - creating perfect returns and backs. Whether you're a seasoned professional or just getting started in the sign industry, mastering these fundamentals is essential for producing high-quality illuminated signage.

The Basics of Channel Letter Components

Before we get into the specifics of returns and backs, let's break down what we're working with:

Face material

Return (the sides)

Back

LED modules

Trimcap

Understanding Returns in Channel Letter Construction

Returns are the sides of channel letters that give them their depth. The quality of your returns can make or break the overall appearance of your channel letters.

Key considerations for returns include:

Material selection

Proper measuring

Clean cutting techniques

Precise bending

Material Selection for Returns

The most common materials used for returns are:

Aluminum

Stainless steel

Galvanized steel

Creating Professional Channel Letter Backs

The back of a channel letter might not be visible to the end user, but it's crucial for:

Weather protection

Housing electrical components

Overall structural integrity

Essential Steps for Back Fabrication

Accurate measurements

Proper material selection

Clean cutting

Weatherproofing considerations

Tools and Equipment Needed

For professional channel letter fabrication, you'll need:

Metal cutting tools

Bending equipment

Measuring devices

Safety equipment

Tips for Quality Assurance

To ensure the highest quality in your channel letter fabrication:

Double-check all measurements

Test fit components before final assembly

Ensure proper weatherproofing

Verify electrical component spacing

Safety Considerations

Remember these important safety points:

Wear appropriate PPE

Follow electrical codes

Maintain a clean workspace

Use proper ventilation

Industry Standards and Best Practices

When fabricating channel letters in the Bay Area, it's essential to adhere to:

Local building codes

UL standards

Electrical requirements

Installation specifications

This guide serves as a starting point for channel letter fabrication. Remember that quality craftsmanship comes with experience and attention to detail. For Bay Area sign makers, understanding these fundamentals is crucial for creating durable, professional-looking channel letters that meet both client expectations and industry standards.

Stay tuned for more sign-making insights and technical guides to help you perfect your craft!

Contact Information

For more information about channel letter fabrication or sign-making services in the Bay Area, feel free to reach out to local sign-making associations and professional organizations for guidance and resources.