Powder Coating Metal Signs: Your Guide to Temperature and Thickness Control for the Perfect Bay Area Finish

Understanding the Fundamentals of Powder Coating for Metal Signs

Let's talk about something that's crucial for achieving those stunning, durable metal signs we see throughout the Bay Area - powder coating. Whether you're in San Francisco, Oakland, or San Jose, understanding the science behind powder coating can make all the difference in sign durability and appearance.

The Importance of Temperature Control

Temperature control stands as one of the most critical factors in powder coating metal signs. The process requires precise temperature management during both the preheating and curing stages.

Key Temperature Considerations

Preheating metal typically requires temperatures between 350-400°F

Most powder coatings cure at temperatures ranging from 350-400°F

Curing time usually spans 10-20 minutes after reaching temperature

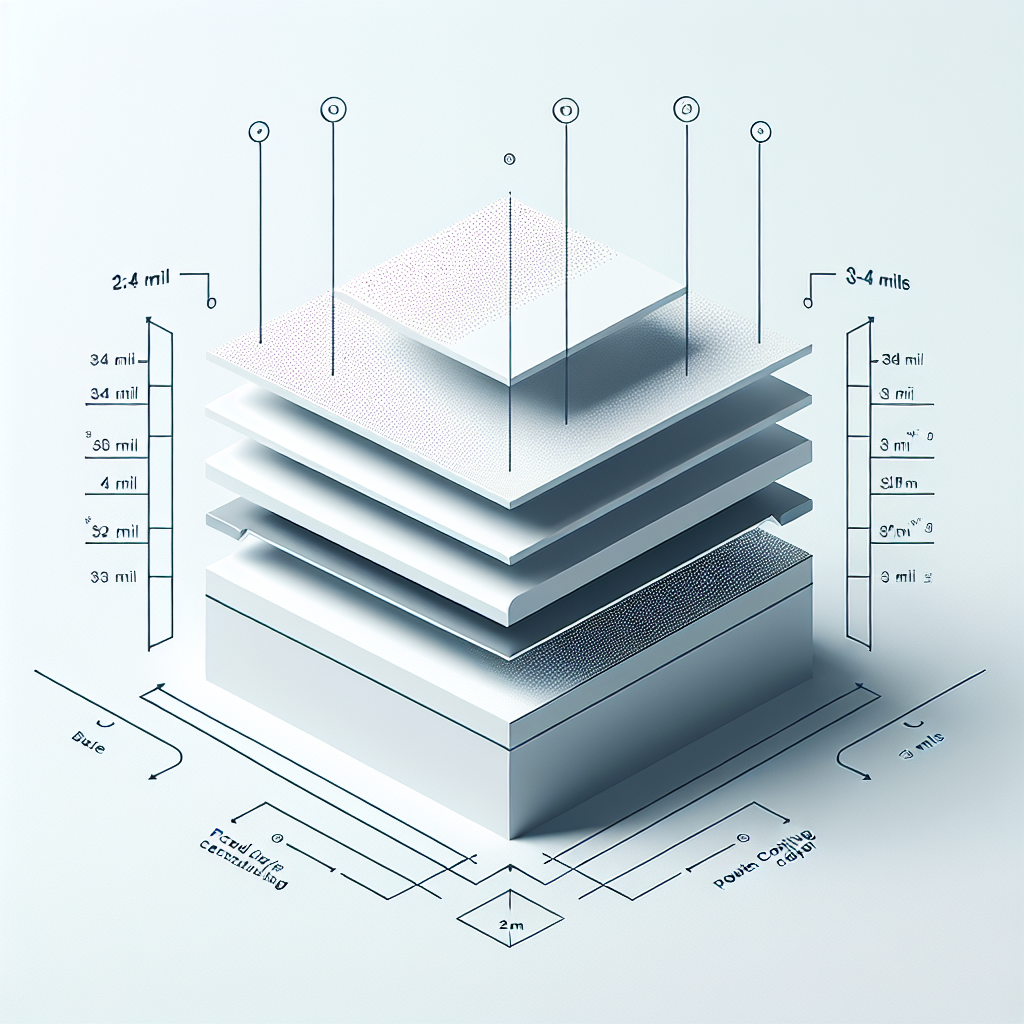

Thickness Control: The Foundation of Quality

The thickness of your powder coating directly impacts the sign's durability and appearance. Too thin, and you risk inadequate coverage. Too thick, and you might face texture issues or poor adhesion.

Optimal Thickness Guidelines

Interior applications: 2-3 mils thickness

Exterior applications: 3-4 mils thickness

High-wear areas: 4-6 mils thickness

Environmental Considerations in the Bay Area

Our unique Bay Area climate presents specific challenges for powder coating. The varying humidity levels and coastal air require careful attention to:

Proper surface preparation

Moisture control during application

Appropriate thickness selection for marine environments

Quality Control Measures

Achieving consistent results requires systematic quality control:

Temperature monitoring throughout the process

Regular thickness testing

Visual inspection for coverage uniformity

Adhesion testing when appropriate

The Value of Professional Equipment

Professional powder coating requires specific equipment:

Accurate temperature gauges

Thickness measurement tools

Quality powder coating guns

Professional-grade ovens

Common Troubleshooting Tips

Understanding potential issues helps maintain quality:

Orange peel texture often indicates improper temperature

Uneven coverage may result from inconsistent application

Poor adhesion typically relates to inadequate surface preparation

Remember, powder coating is both a science and an art. The Bay Area's sign industry demands excellence in both appearance and durability, making proper temperature and thickness control absolutely essential.

Environmental Benefits

Powder coating offers significant environmental advantages:

Zero volatile organic compounds (VOCs)

Recyclable overspray

Energy-efficient curing processes

Maintenance Recommendations

To maintain powder-coated signs:

Regular cleaning with mild soap and water

Avoid abrasive cleaners

Periodic inspection for damage

This guide provides a foundation for understanding powder coating metal signs. Remember, professional expertise ensures the best results for your signage projects in the Bay Area's demanding environment.